Applications

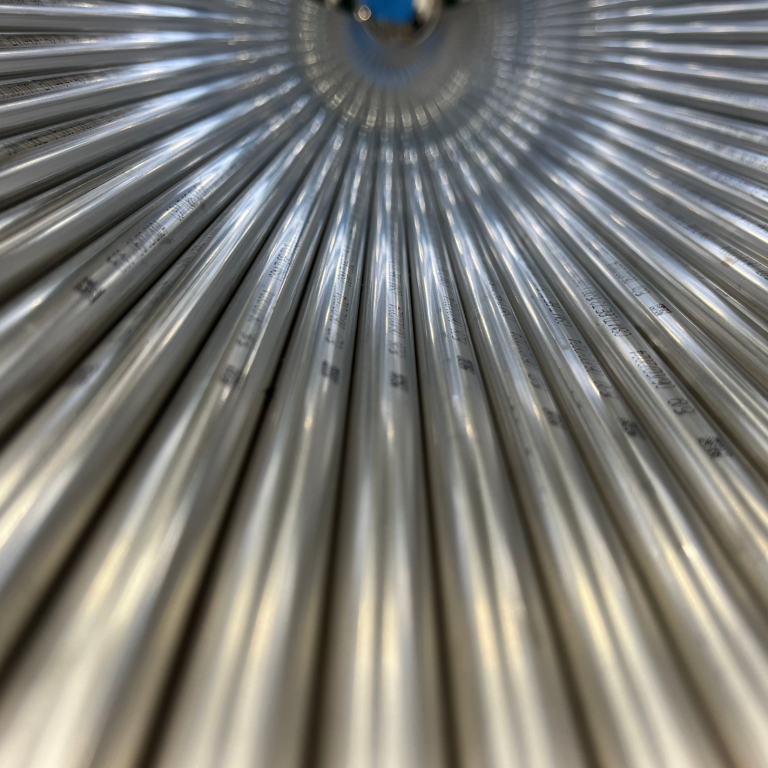

TUBE PROCESSING

Custom tube processing

Tube processing is one of CSM TUBE's specialties. Our customised stainless steel tubes are versatile, catering to a wide range of applications—from automotive manufacturing to the production of household appliances like refrigerators, and even solar collector systems.

How we work

Customisation

We are able to provide a wide range of processing thanks to our ability to create tailor-made solutions. We have invested in the latest stainless steel tube bending technology and the technical and technological knowledge required to design and manufacture custom-made tubes to the highest standards.

Tube processing techniques

Our team can apply a variety of special tube processing techniques. In some cases, a standard bending machine is used, while in other cases, hot induction bending is available. Whichever process is used, our tubes retain their characteristics and can be used in complex applications. They are also available in various formats, including AISI and high-nickel and heat-treated alloys, while diameters and thicknesses can be ordered on request.

Tube specifications

-

Diameter: from 5.00 mm to 32.00 mm

-

Wall thickness: from 0.30 mm to 2.00 mm

-

Length bar tubes: up to 20 meters

-

Length coiled tubes: up to 2,000 meters, pressure-tested up to 70 bar

Product Range

CSM TUBE’s stainless steel tube production can meet a wide range of specifications.

Quality

We conduct a full range of tests throughout the entire manufacturing process.

Alloys

A detailed table is available that specifies the alloys and chemical composition of our tubes.

Application sectors

Our stainless steel tube production methods can meet the needs of a wide range of industrial applications.

Our tubes find applications in heat exchangers, heating elements, and various heating systems and devices.

s.

Our commitment to high-quality production has solidified our position as a market leader, serving strategic industries such as energy, food and beverage, and automotive sector.

Contact us

Want more information? Our technical team will get back to you as soon as possible with support.

Fields marked with an asterisk (*) are mandatory. Please accept our privacy policy before sending your request.